Throughout various industries, control of water quality is critical to the proper operation of equipment and for maintaining compliance with Environmental Protection Agency standards. One important criterion for water relates to the number of solids in water. Total Dissolved Solids, or TDS, is a measure of the amount of soluble material dissolved in the water. This includes solids such as salts (NaCl, Ca(OH)2, etc). Total Suspended Solids, or TSS, is a measure of the amount of insoluble material in the water. This includes solids such as silt, sludge, or catalyst materials. Total Solids, or TS, is a combination of both the dissolved solids (TDS) and suspended solids (TSS). Often, the goal for water processing is to remove as many of these impurities as possible. This is often accomplished using methods such as a reverse osmosis unit.

In some applications, specifically where there is a “concentrator”, such as a boiler or evaporator, it is necessary to control both the concentration of dissolved solids in the liquid, such as salts, and the concentration of insoluble solids suspended in the liquid. If a simultaneous reduction of both is desired, a simple drain and re-fill (or blowdown) of the storage system may be adequate. However, if there is a need to change one without the other, then some means of separation must be employed.

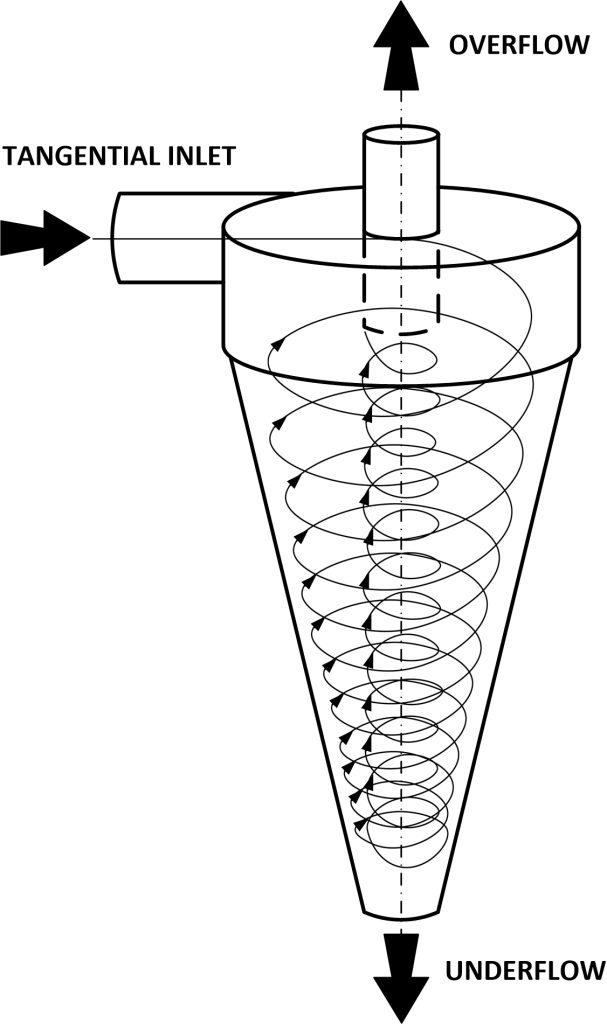

One method which can be used to control the TDS and TSS concentrations independently is by using a cyclone separator, also known as a hydrocyclone. A hydrocyclone is a device which imparts a swirling or “cyclone” action on a liquid as it enters the cyclone. Due to this flowpath, liquid with a higher concentration of TSS is forced towards the bottom of the hydrocyclone; liquid with a lower concentration of TSS is forced towards the top. Note that the TDS concentrations of both are the same.

Water with a high TSS concentration is discharged from the bottom of the hydrocyclone, and is referred to as “hydrocyclone underflow”. Water with a low TSS concentration is discharged from the top of the hydrocyclone, and is referred to as “hydrocyclone overflow”.

To control the TSS and TDS concentration, a control loop can be used.

The liquid (brine) to be controlled is recirculated from the “concentrator” by a recirculation pump. A portion of this flow is directed to the hydrocyclone via a dedicated hydrocyclone feed pump and isolation valve.

As the liquid enters the hydrocyclone, high TSS liquid flows to the hydrocyclone underflow and is recirculated back to the concentrator. This results in the TSS level in the concentrator remaining constant or increasing.

As the liquid enters the hydrocyclone, the cyclone action causes liquid with a low TSS concentration to rise to the top of the hydrocyclone. The liquid flows to the hydrocyclone overflow, and can be directed back to the concentrator via the Hydrocyclone Overflow Recycle Valve and Recirculation Pump. Recycling the liquid back to the concentrator causes the TDS levels in the concentrator to remain constant or increase.

Rather than being recycled, low TSS concentration liquid from the hydrocyclone overflow can also be discharged to a blowdown tank via the Blowdown Flow Control Valve. Discharging the liquid causes the TDS levels in the concentrator to decrease.

If it is necessary to lower TSS levels in the concentrator, the Total Solids Flow Control Valve can be used to bypass the hydrocyclone and direct flow from the concentrator directly to the blowdown tank via the Recirculation Pump. This results in a reduction of both the TDS and TSS levels in the concentrator.

Although the process of controlling Total Solids using a cyclone is fairly simple, the addition of instrumentation, such as conductivity meters (an indication of TDS), density meters (an indication of TSS), and automated valves can make the entire process automatic. Although this automatic system can provide ease of operations, a well trained staff is critical to ensuring its proper function.

The control of Total Solids using a hydrocyclone has several applications within industrial facilities, such as recycling facilities and power generation facilities. In power generation, the use of a hydrocyclone can be used to treat wastewater streams, such as those that come from the flue gas desulfurization process.

Water quality control is a complex topic. Standards for water quality vary based on numerous guidelines based on what the water is being used for and where the water is being discharged to. It is critical to maintain proper control of water quality to ensure compliance with these standards. Not all water treatment systems produce the same standard of water quality and thus, the method used to control water quality depends on which of these standards are applicable for the given circumstances.

Which water treatment system is right for your facility?