There is a nationwide push for the retirement of ash ponds. Since the need for ash storage remains, many plants are looking toward ash recycle systems, dry ash handling systems, or other technology to dispose of the ash.

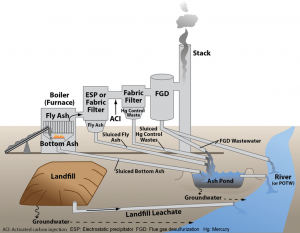

Ash ponds, which have been in use for the past two centuries, store two unwanted byproducts of coal combustion: bottom ash and fly ash. These ash ponds, also called surface impoundment, use gravity to settle ash from power plant wastewater in large holding ponds. Some newer ash disposal systems do not use ponds and instead collect the ash in large hoppers or tanks where the ash may later be disposed of in a landfill or recycled. Economic perspectives typically prefer ash ponds. However, environmental perspectives typically prefer alternative ash disposal systems.

Ash ponds are designed and constructed to prevent seepage and ensure slope stability through ring embankments to enclose the ponds. However, time has tested many of these ponds and unfortunately, extended use without proper inspections and maintenance has led to numerous ash spills to adjacent land and rivers across the country. These ash spills result in severe environmental damage with d long-term effects. Two examples of significant ash spills in recent history are:

Obviously, nobody wants toxic ash released into their local waterways where they fish, swim, and obtain drinking water. Power producers and energy conglomerates do not want to damage their reputations, pay fines, and fund enormously expensive cleanups. As a result, power producers and energy companies are retiring ash ponds. They are replacing them with ash recycle systems, dry ash handling systems, or other alternative ash disposal systems. Plants should increase inspection frequency and line ash ponds when leaks are discovered. This isn’t practical but will decrease the risk of ash pond failures.

While many responsible power producers and energy companies are proactively taking steps to prevent ash pond seepage and leakage into local waterways, the EPA is going a step further to ensure disasters like those at Kingston and Dan River do not recur. In 2015, the EPA imposed new rules and regulations for the safe disposal of coal ash from power plants. Plants should expect to implement this over the next few years despite the current hold for amendments.

Plant ownership and management must ensure steps to avoid ash spills by being aware of the risks. They can eliminate or reduce risks by complying with the new EPA regulations. Further, operators and maintenance personnel must adequately train on new inspection and maintenance requirements required by the EPA. Ash pond retirement and replacement require training efforts.

If your plant is looking for training on a system that has replaced an ash pond, FCS can help!