When operating induced draft cooling towers during cold weather (wet bulb temperature less than 32°F), one of the prime considerations is the prevention of icing of the inlet louvers or fill. When excessive ice accumulates, the additional weight can sometimes collapse the air louvers, fill, and even the entire cooling tower itself. It is essential that operators monitor the cooling towers for ice buildup during cold weather, understand the importance of keeping ice buildup within safe levels, and know how to take action to reduce ice buildup if necessary.

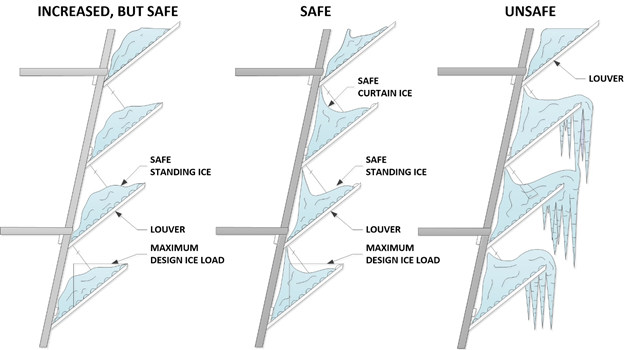

Most induced draft cooling tower air inlet louvers are designed for some level of ice buildup. This level of ice buildup is commonly referred to as “Safe Ice”, defined as safe standing ice and as shown in the figure below.

Levels of unsafe ice are also illustrated in the figure. When unsafe levels of ice form, the integrity of the cooling tower can be put in jeopardy.

To prevent unsafe ice levels during cold weather, operators should adhere to several principles of cooling tower operation in cold weather1. These principles include:

In the event unsafe levels of standing and curtain ice form on a cooling tower, there are actions that operators can take to reduce ice buildup on the cooling tower. Common actions that operators can take include:

Cooling tower air inlet louvers are angled inward to keep the process fluid from splashing out of the cooling tower while also allowing for maximum air flow into the tower. Ideally, if the angle of the louvers is correct, any water that escapes the cooling tower fill would be drawn into the cooling tower to reduce makeup water usage. Also, the louvers are not angled so much that they make it difficult for air to flow across the louvers and into the tower fill. With that said, by design, some water is meant to escape the cooling tower fill, coat the louvers to allow a flow of warm water across the louvers during normal operation and be ultimately drawn in by the airflow into the cooling tower.

If the airflow into a cooling tower is reduced, by slowing or stopping the fans, the water that would have been previously drawn into the cooling tower will instead wash over the louvers. As the process fluid is warm, it’s washing over the louvers will melt the ice. It is therefore possible to de-ice cooling tower louvers by stopping or reducing the speed of the cooling tower fans.

Understanding ice buildup on cooling towers and the importance of maintaining ice buildup within safe levels is critical to the operators’ ability to operate their cooling towers safely and efficiently. Management should ensure their operators are professionally trained on the operation of cooling towers during cold weather, site-specific cooling tower controls and equipment, and how the cooling towers should be operated during varying ambient conditions.

Inadequate training can often result in allowing cooling tower ice buildup to reach unsafe levels during cold weather. This can force unplanned shutdowns and result in costly repairs. Further, the cold weather conditions that place cooling towers at increased risk for icing are often also the conditions of peak demand. An unplanned shutdown during these periods can result in lost revenue at a time where the plant would have been most profitable.