Several factors affect the cost of generating one Mega-Watt hour (MWh) of electricity in a power plant; each is discussed in the following paragraphs. A power plant may be thought of as an “energy conversion factory. We should examine the physical laws governing energy to understand energy conversions. The First Law of Thermodynamics, also known as the Law of Conservation of Energy, states that:

Energy can neither be created nor destroyed; energy can only be transferred or changed from one form to another.

For example, turning on a light would seem to produce energy; however, it is electrical energy that is converted to heat energy and light energy.

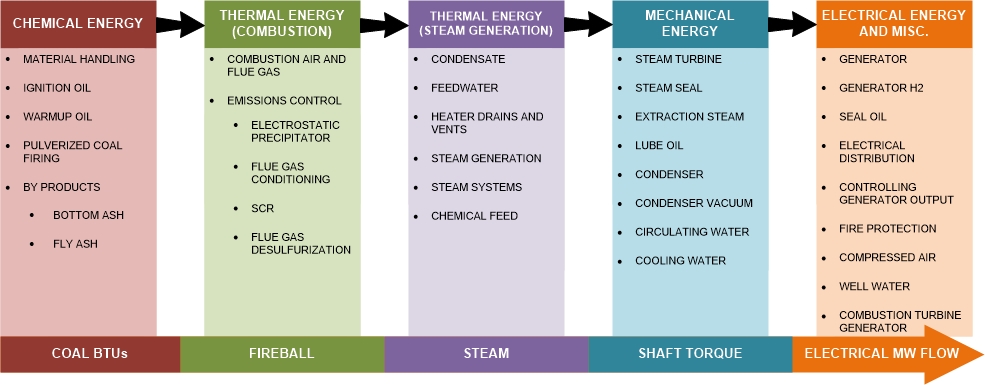

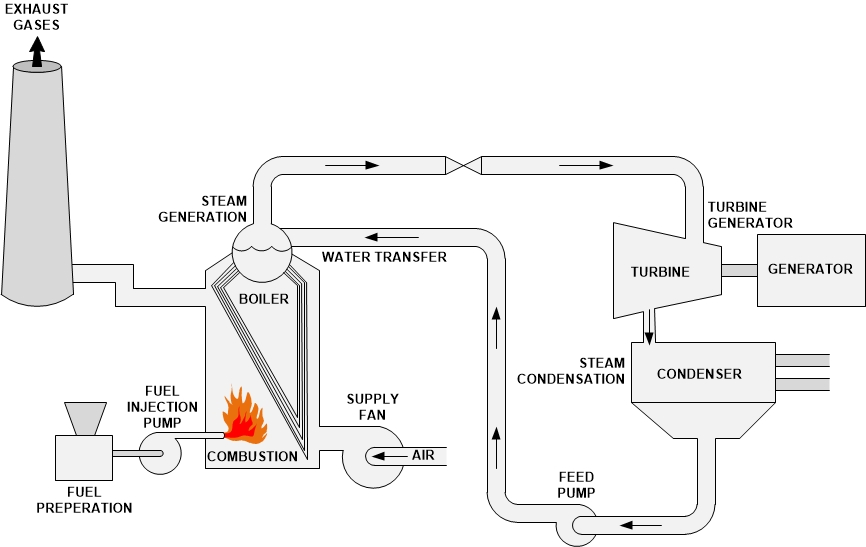

Fossil power plants convert energy from one type (chemical energy in coal or other fuel) to another type (electrical energy). The four major steps in the energy conversion process are:

The cost of generating an MWH includes the capital cost (cost to build/purchase the plant), the financing charges, and the production or operating costs (including fuel, operations, and maintenance) at the connection point to an electricity grid.

Factors that affect the cost of generating electrical power include:

Typical Rankine cycle plant efficiency is only about 35%. The most significant component of the cost of operation of a power plant is fuel. A slight drop in fuel cost results in significant savings, increasing competitiveness.

When discussing plant efficiency, the term Heat Rate is used. Heat rate is the inverse of efficiency (lower heat rates represent higher efficiencies). Heat rate is defined as:

Energy Input/Energy Output

Heat Input (BTU)/Generator Output (kWh)

BTU/kWh

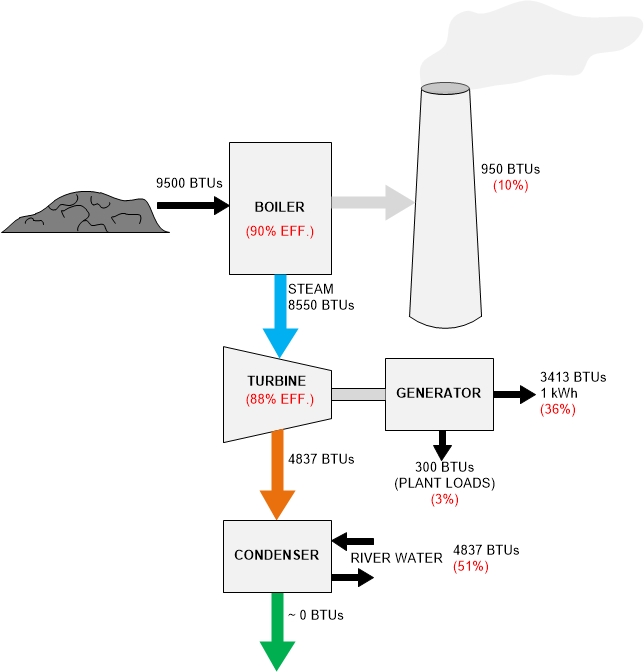

Since 3,413 BTU = 1 kWH, the heat rate of a 100% efficient plant would be 3,413 BTU/kWH. The heat rate of a real plant is usually between 8,500 – 13,500 BTU/kWH.

Let’s use an example 850,000 kW power plant that burns about 4.5 million tons of coal per year at an annual cost of 130 million dollars. Let’s also assume our sample power plant operates at a plant heat rate of 9,500 BTU/kWh (35.9% efficiency).

3,413/9,500 = 35.9%

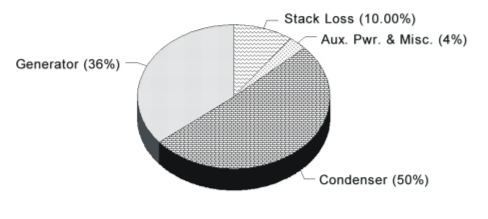

For this sample plant with a heat rate of 9,500 BTU/kWH, only 35.9% (rounded to 36%) of the heat from the fuel burned is converted to electrical power – the rest is lost. As shown below, major losses come from:

To calculate the annual fuel cost at the plant, take the product (multiplied) of:

Heat Rate X Unit Rating X Fuel Cost X Load Factor X 8,760

9,500 BTU/kWH X 850,000 kW X $2.30/MBTU X 0.8 X 8,760 Hours/Year =

Fuel Cost of $130,156,080/Year

Other costs involved in getting an MWh to market include:

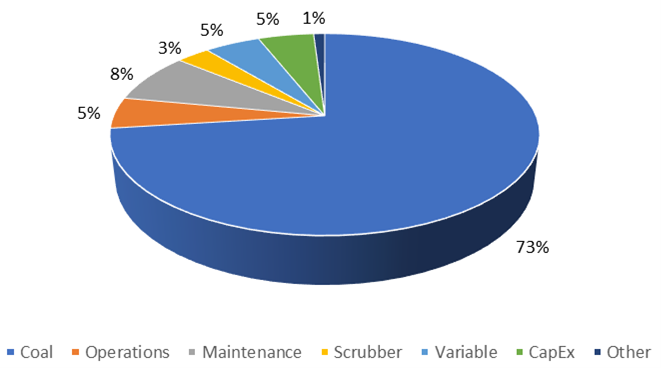

This data is shown as a pie chart below. As can be seen, the coal cost is by far the highest operating cost.

Given that the fuel cost is the largest cost, this is the easiest place to find savings in the total cost of generating an MWh. Going back to the previous calculation, a modest improvement of 100 BTU/kWh, to 9,400 BTU/kWh (approximately a 1% improvement in plant efficiency), will result in savings of about $1,287,860/Year!