Winter and spring are behind us, and temperatures are on the rise. However, the pleasant shift from short days and cold nights comes with its challenges. Higher ambient temperatures place a larger load on air conditioning systems. Those responsible for paying the utility bills will attest that the increase in energy consumption and subsequent cost can be significant.

Most people are familiar with air conditioning units that maintain the temperature in a building or smaller space. An individual cooling system such as this is suitable for a home or small building. For a group of larger buildings in proximity, a centralized cooling plant is more economical and efficient.

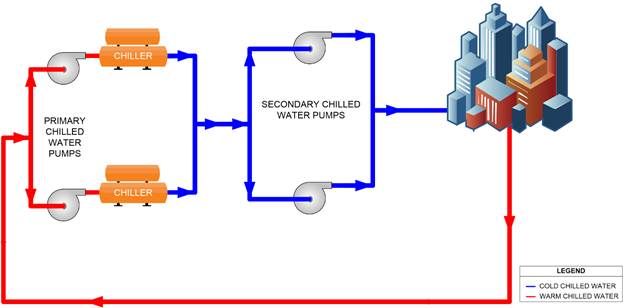

Centralized cooling plants are used to meet district energy cooling needs. Inside a centralized cooling plant are chillers, which use the refrigeration cycle to remove heat from the Chilled Water System. The Chilled Water System circulates cold chilled water from the chillers for use in air conditioning and other cooling applications, and returns the warm chilled water to the chillers. A network of pipes distributes the chilled water to the users and subsequently returns it to the plant. Shown below is a simplified graphic of a Chilled Water System.

The above diagram shows two of the major components of a Chilled Water System, primary chilled water pumps and the secondary chilled water pumps. The function of primary chilled water pumps is to maintain a constant flow of chilled water through the chiller evaporators. Chillers require chilled water flow at the design rate for proper operation.

The function of the secondary chilled water pumps is to deliver chilled water to the district energy users. A common method of supplying the required chilled water flow under fluctuating conditions is the use of variable frequency drives (VFDs). Equipping the pump motor with a VFD allows for the adjustment of pump speed. As chilled water load fluctuates throughout the day, the pump speed changes to deliver the required chilled water flow.

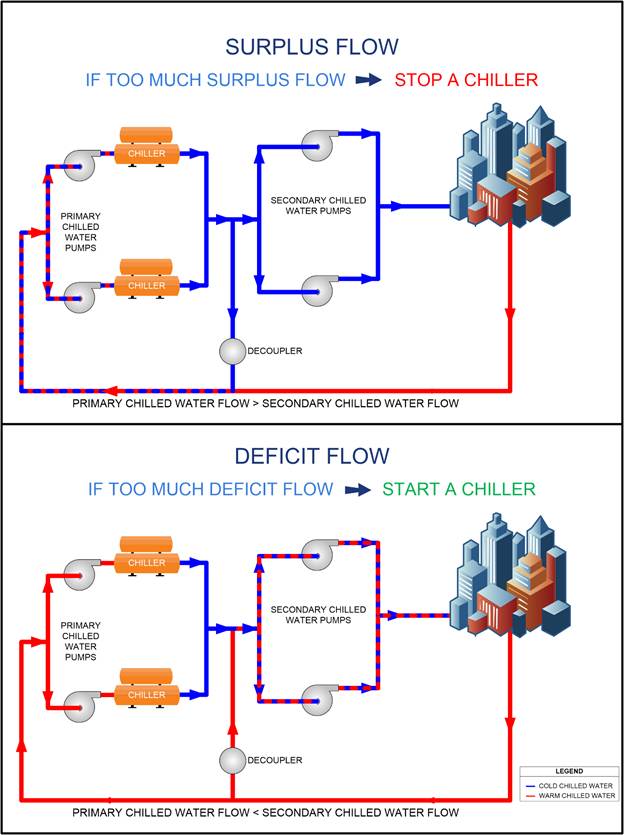

The operating speed of the secondary chilled water pumps changes with cooling load. Therefore, total flow generally differs from total primary chilled water pump flow. Since the primary and secondary chilled water pumps are connected in series, the Chilled Water System is designed with a provision to allow for these differences in flow. This provision is a device called the decoupler.

The function of the decoupler is to account for flow imbalances between primary and secondary chilled water. The decoupler is simply a pipe with a flow meter that connects the suction lines of the primary and secondary chilled water pumps. While the decoupler is basic, it is crucial to the system design.

During a surplus flow condition, flow through the chillers (primary flow) is greater than the flow through the secondary pumps (secondary flow). There is recirculation of cold chilled water from the chiller discharge header back to the warm chilled water return header. When this situation occurs, the temperature of the chilled water supplied to the chillers drops, indicating there are sufficient chillers in service to meet the cooling demand.

During a deficit flow condition, secondary chilled water flow exceeds primary flow. Some of the warm chilled water returning from the users bypasses around the operating chillers. This leads to an increase in secondary chilled water temperature and subsequently primary chilled water temperature. Temperatures will continue to increase with secondary chilled water flow greater than primary chilled water flow.

Best practice is to operate the Chilled Water System at a slight surplus condition. If surplus flow becomes excessive, the operation is inefficient. Stopping a chiller alleviates an excessive surplus condition. If a deficit flow condition becomes excessive, the system may not be able to meet the demand of the district energy users. Starting a chiller corrects an excessive deficit condition.

The effective and efficient operation of a Chilled Water System starts with a strong level of knowledge. Plant personnel must understand the operation of a Chilled Water System that converts a large amount of energy to provide a critical service. FCS is prepared to provide your facility with technical training services that will ensure a successful operation!