As the US population continues to rise and the regulatory belt continues to tighten around emissions, power plant owners and operators must continue to look toward emerging technologies to maintain their competitiveness. One emerging technology in the power industry is supercritical carbon dioxide (SCCO2) and its use in the Allam-Fetvedt Power Cycle.

The Allam-Fetvedt cycle differs from traditional power plants (Rankine and Brayton) cycles in that emissions can be reduced close to net-zero. And the plants operate at higher efficiency. Further, unlike many other theories and ideas to reduce emissions, this technology has been built, tested, proven, and commercialized at a plant in La Porte, Texas1.

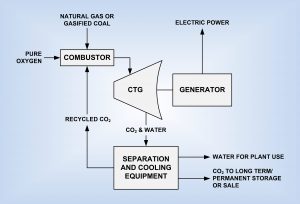

The Allam-Fetvedt cycle burns fuel with a mixture of oxygen and recycled CO2 instead of atmospheric air which is typically mixed with fuel in traditional power plants. As atmospheric air is mostly nitrogen, burning a mixture of CO2 and oxygen in lieu of atmospheric air greatly reduces the formation of NOX in the combustion process. Also, by recycling the CO2 generated in the combustion process through carbon capture technology, CO2 emissions can be drastically reduced and, in some cases, eliminated altogether.

The La Porte, Texas plant pairs the Allam-Fetvedt cycle with the use of supercritical carbon dioxide (SCCO2) instead of a water/steam cycle2. SCCO2 is near twice as dense as steam and has a high volumetric heat capacity, which allows it to carry more energy per volume than steam. As there is less volume of SCCO2 as a working fluid than steam for the same energy transfer, the size of the equipment in a SCCO2 facility is much smaller3. Smaller equipment helps minimize the overall footprint of facilities and improve efficiency.

Over time as more of these facilities are built and the equipment becomes more common, the smaller equipment size will result in a reduced capital cost and one could suspect that plants using SCCO2 will eventually come with a lower price tag. Further, SCCO2 makes for an ideal working fluid to replace the water in fossil-fueled power plants as it is non-explosive, non-toxic, and reasonably priced compared to many other alternative working fluid options.

As fossil-fueled power plants feel the pressure of tightened emissions standards in a competitive landscape, power plant management and operators should look at the concepts behind the Allam-Fetvedt cycle and supercritical CO2. These concepts can be useful when looking for ways to modify existing facilities to improve both efficiency and emissions.